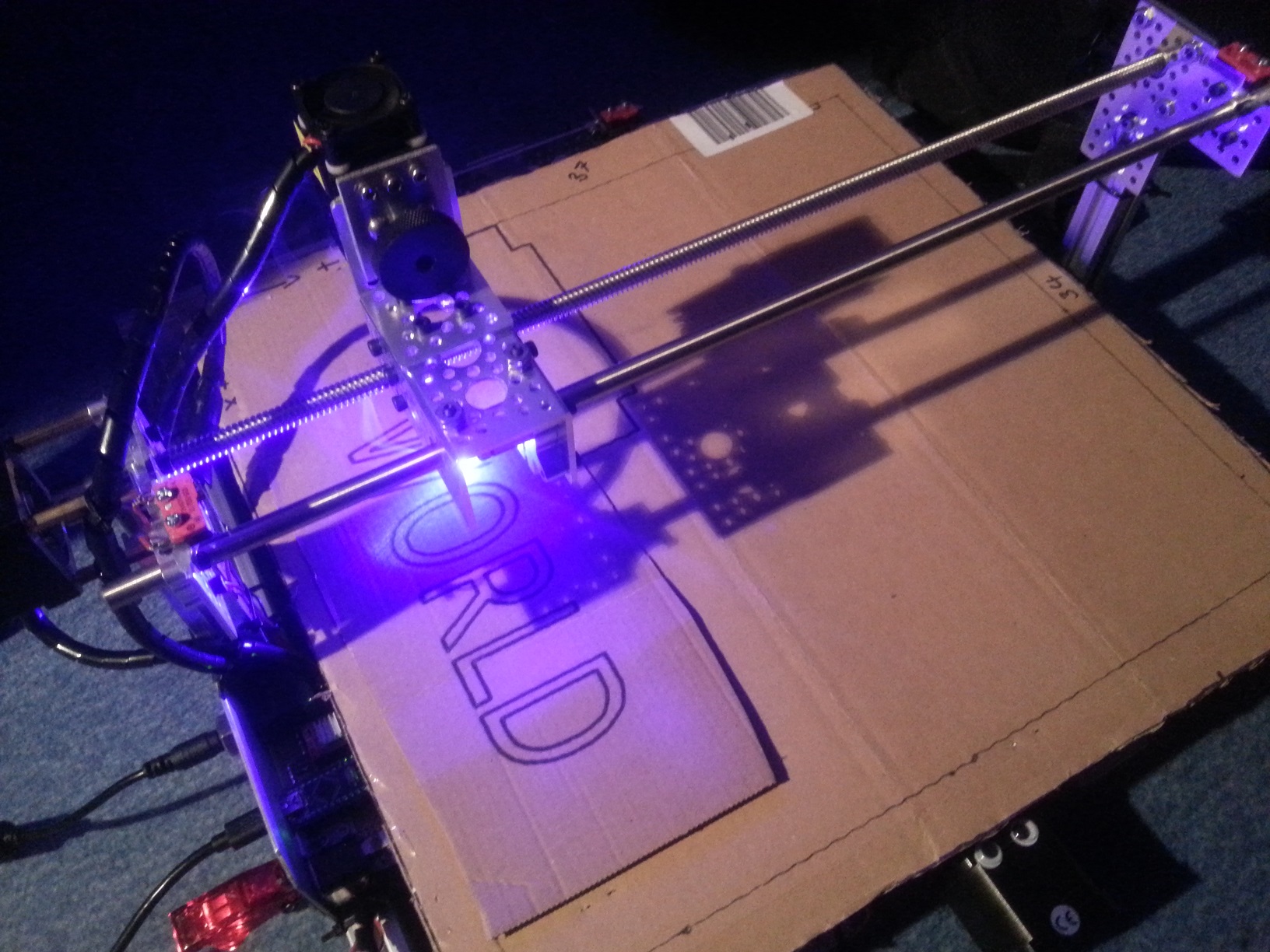

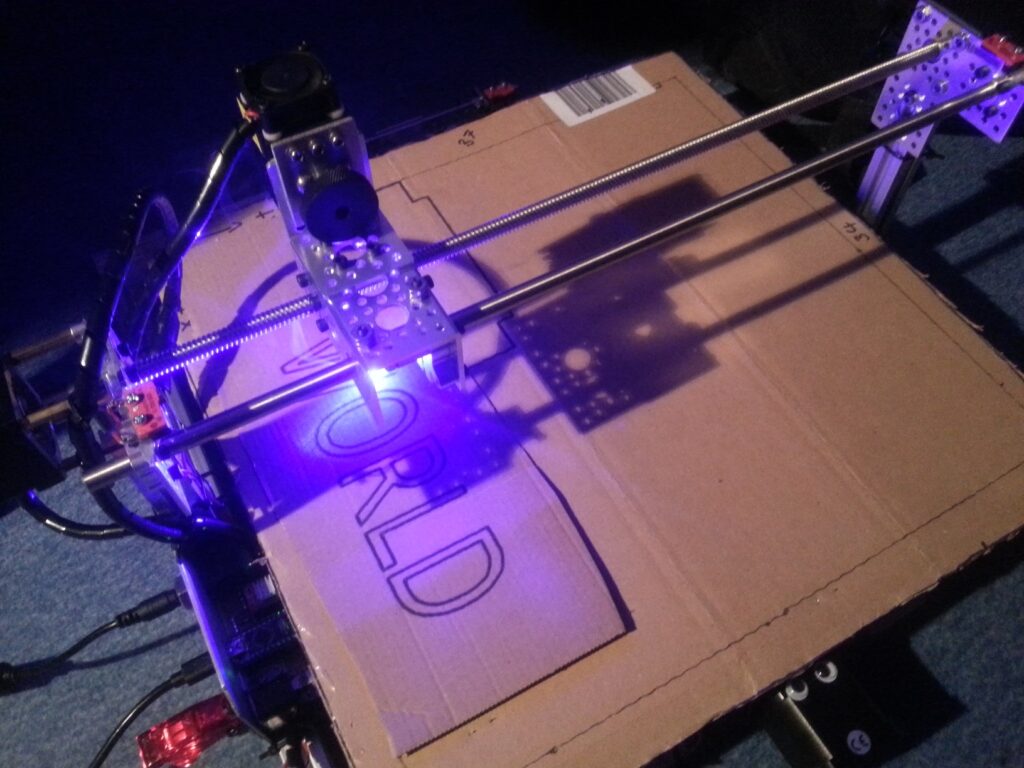

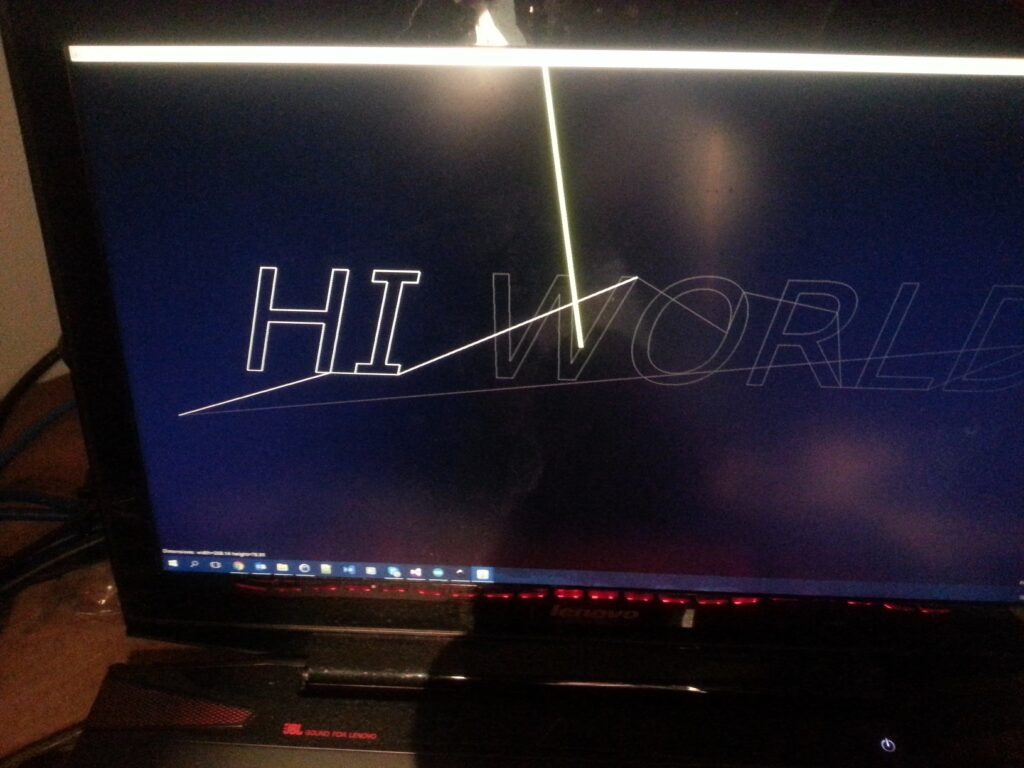

The laser cutter is finally ready for testing! After securing the aluminium base plate (before that I had used carton) I powered up the system and sent my first gcode.

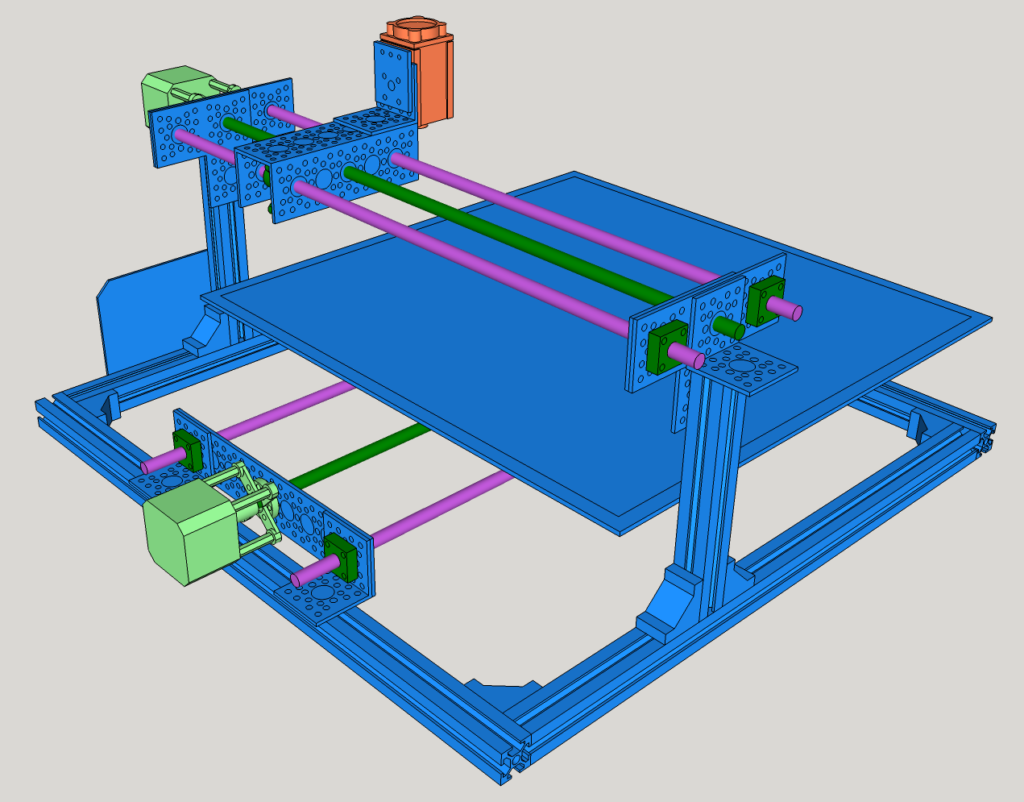

Improving the Y Carriage

Unfortunately, the lasered lines were rather wobbly. This was because the y carriage was only supported by one shaft. So, I ordered more parts.

From Steplab:

- 2 flat triple pattern brackets (https://www.servocity.eu/p/flat-triple-pattern-bracket/) ~5€

- Channel 4.5 (https://www.servocity.eu/p/4-50-aluminum-channel/) ~5€

- 2 screw hubs 8mm patterned (https://www.servocity.eu/p/0-770-pattern-set-screw-hubs-545552/?attribute_diametro=8mm) ~10€

- Steel shaft 8mm 610mm (https://www.servocity.eu/p/precision-shafting-%e2%88%85-8-mm/?attribute_lunghezza=610+mm) ~15€

- Face tapped clamping mount 15mm patterned (https://www.servocity.eu/p/15mm-bore-face-tapped-clamping-hub-1-50-pattern-545678/) ~6€

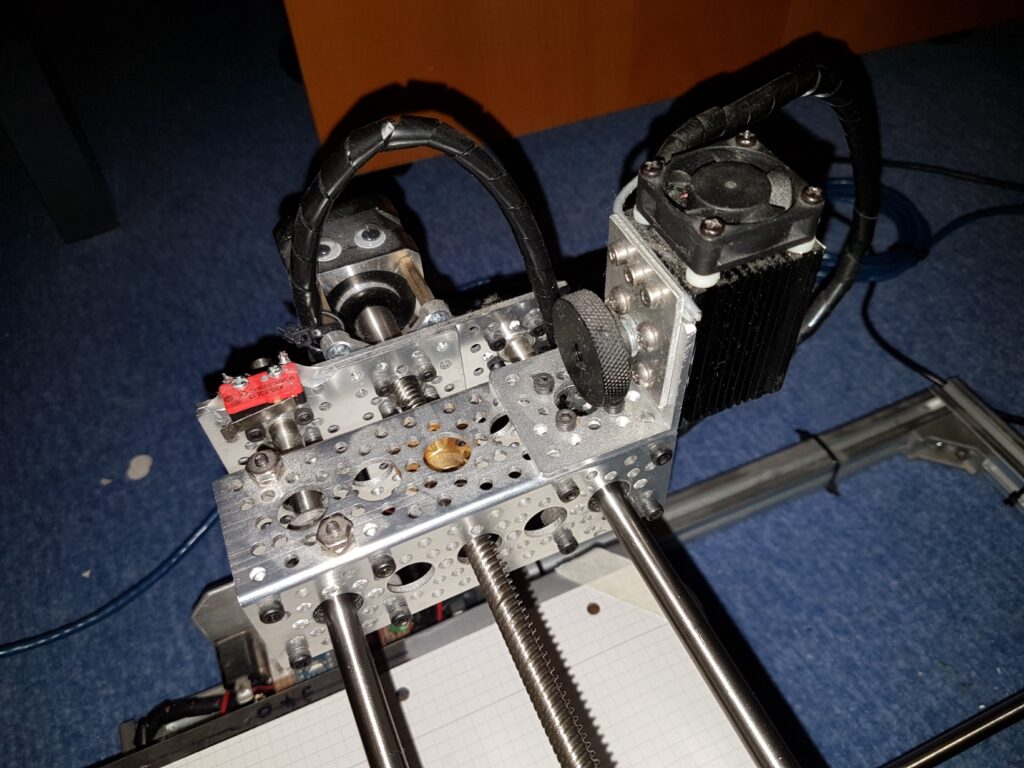

Then, I rebuilt the whole y carriage using the new parts.

And rejoice, the wobble is gone. I produced some beautiful engravings in the time after that.

You can find the other parts of this series here.