After two years of usage, the x carriage of my laser cutter became rather wobbly. Wobbling! My old nemesis! What should I do?

First, I tried to use different bearings. I bought some DryLin PTFE self-lubricating plastic bearings:

But they were no use in my configuration. They tended to bind, and what’s worse, were a lot more flexible and thus wobblier.

More Hardware

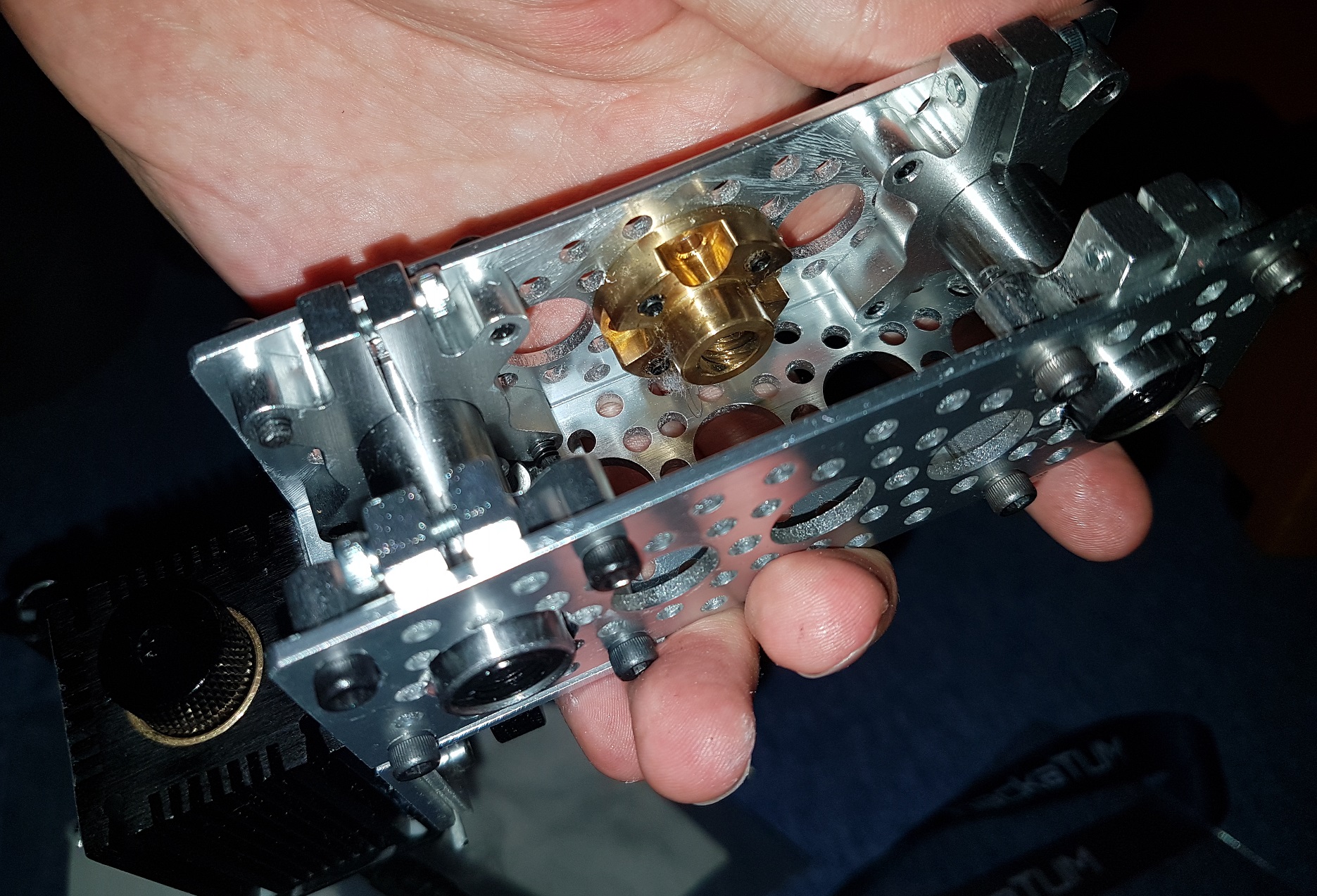

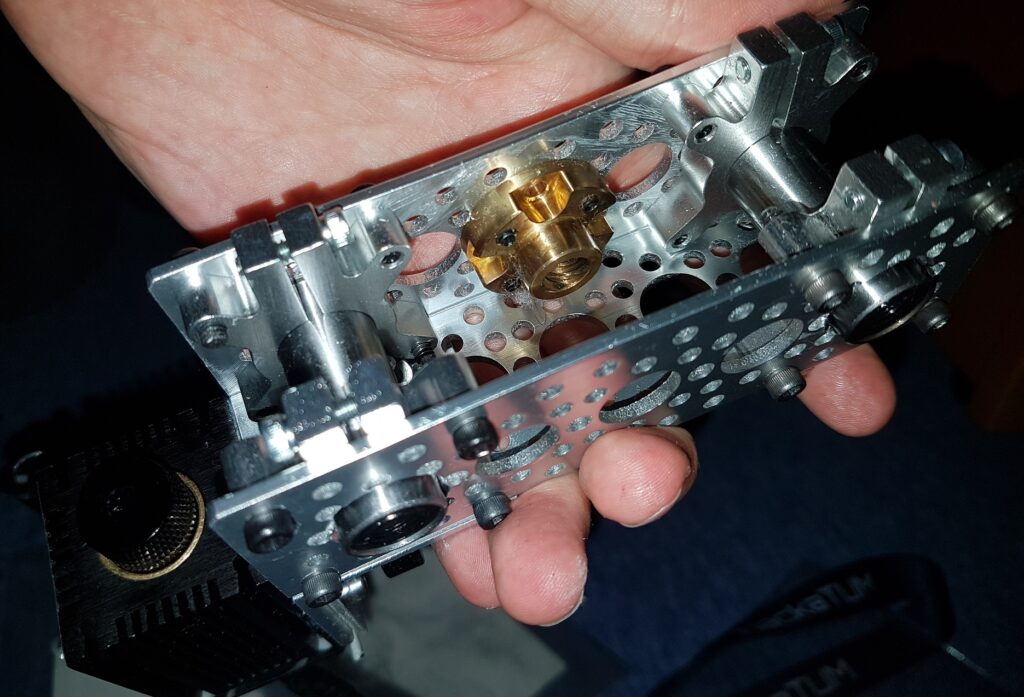

So instead, I opted to buy some longer linear bearings and the fitting mounting clamps. My dear trusty shot at steplab.net does not seem to sell to private custumors anymore that easily, so I purchased the parts from grobotronics.com, a greek shop.

- 4 clamping hubs 15mm patterned (https://grobotronics.com/clamping-hub-15mm-bore.html) ~25€

- 4 linear bearings 8mm 15mm 45mm (https://www.amazon.de/gp/product/B078PBP169) ~10€

I had to drill the aluminium channels so that the bearing could fit though the holes.

Bye Bye Wobble!

Finally, the laser cuts perfectly straight lines and perfectly round circles. Sub-millimeter precision.

It took some adjustments, because the metal guide rods had to be perfectly in parallel, but in the end it was totally worth the effort!

You can find the other parts of this series here.