In 2018, I bought my first and only 3D-printer: The Anet “Firestarter” A8 DIY kit. A few months later, I wrote a post about what upgrades and modifications I did to this printer (No more firestarter). Now, in 2022, I once again upgraded this printer. Like the Ship of Theseus, at what point does it stop being the original printer?… Read More →

Category: Mechanics

Mechanical engineering.

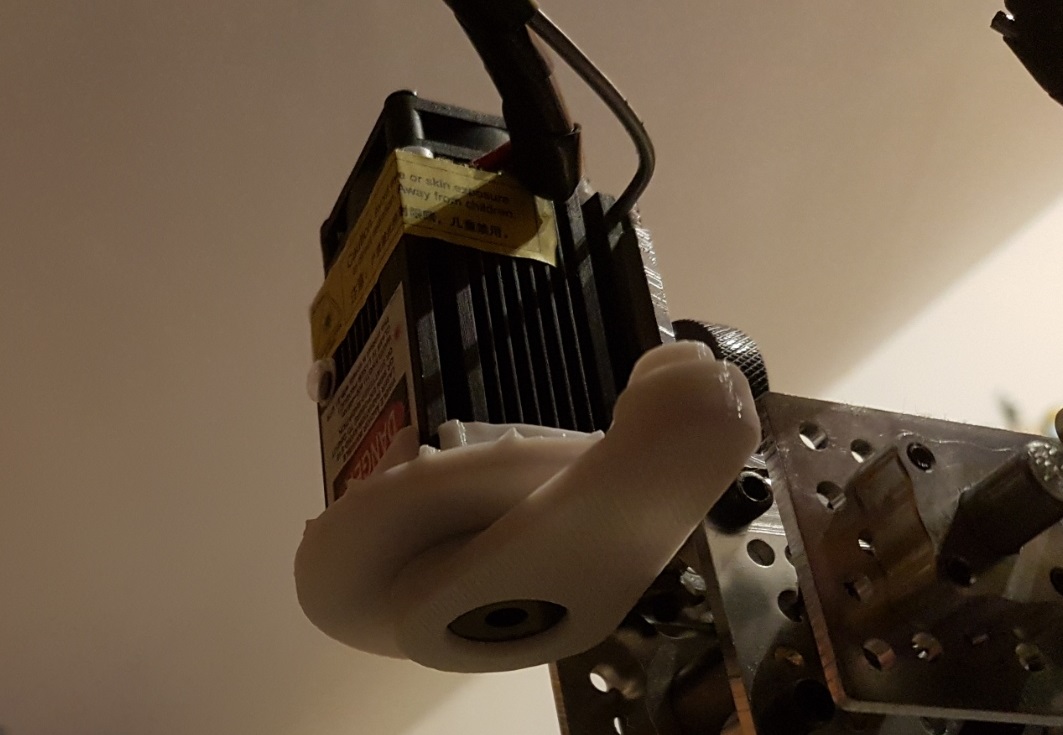

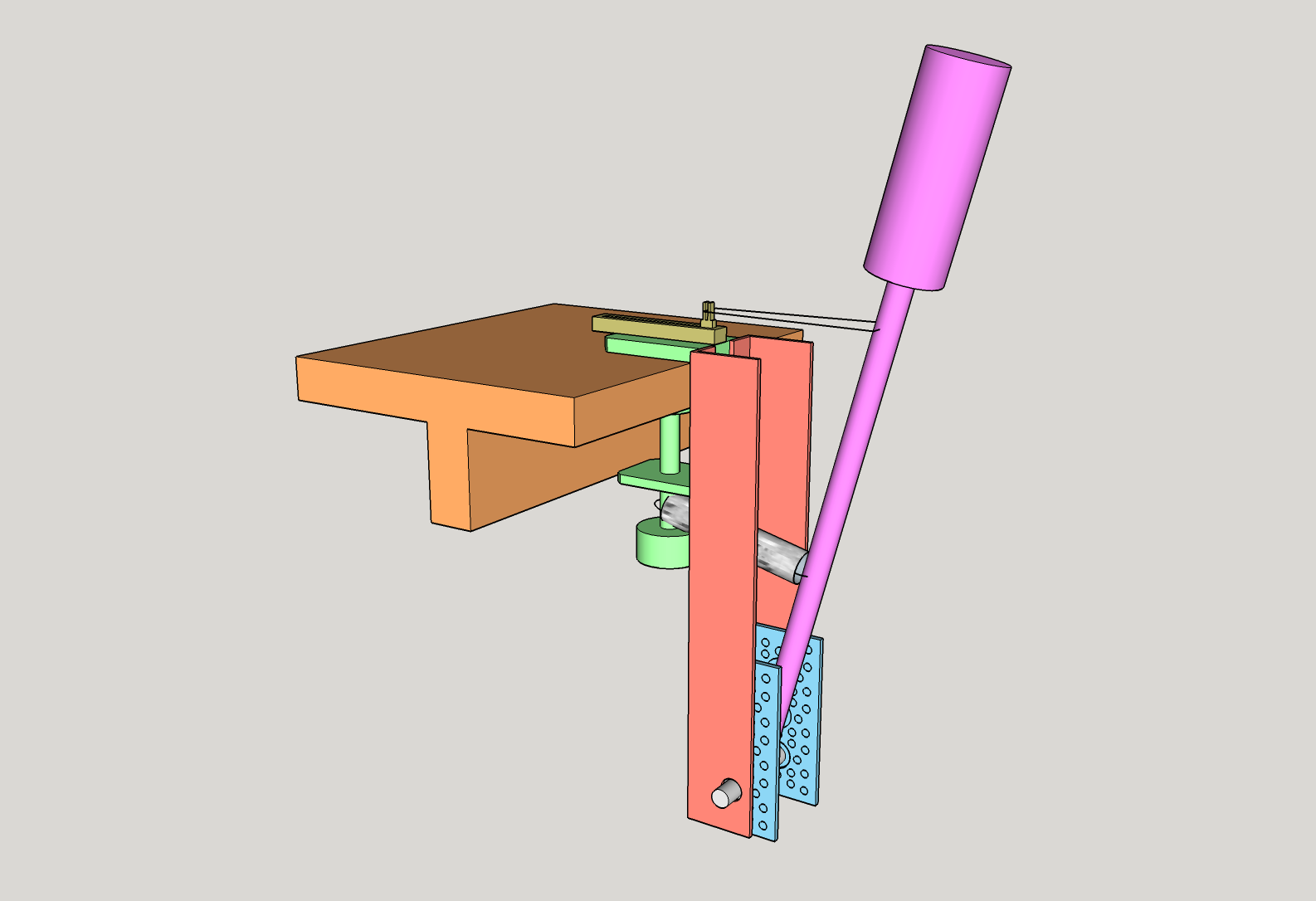

Building a Laser Cutter: Part 6 – Focus Aid

My laser cutter is working perfectly. However, depending on the thickness of the material being cut, the focus of the laser lens needs to be adjusted. This is done by turning the lens screw in front of the laser, which is both finicky and imprecise. To improve this situation, I 3D-printed a small focus-lever with a scale. First things first,… Read More →

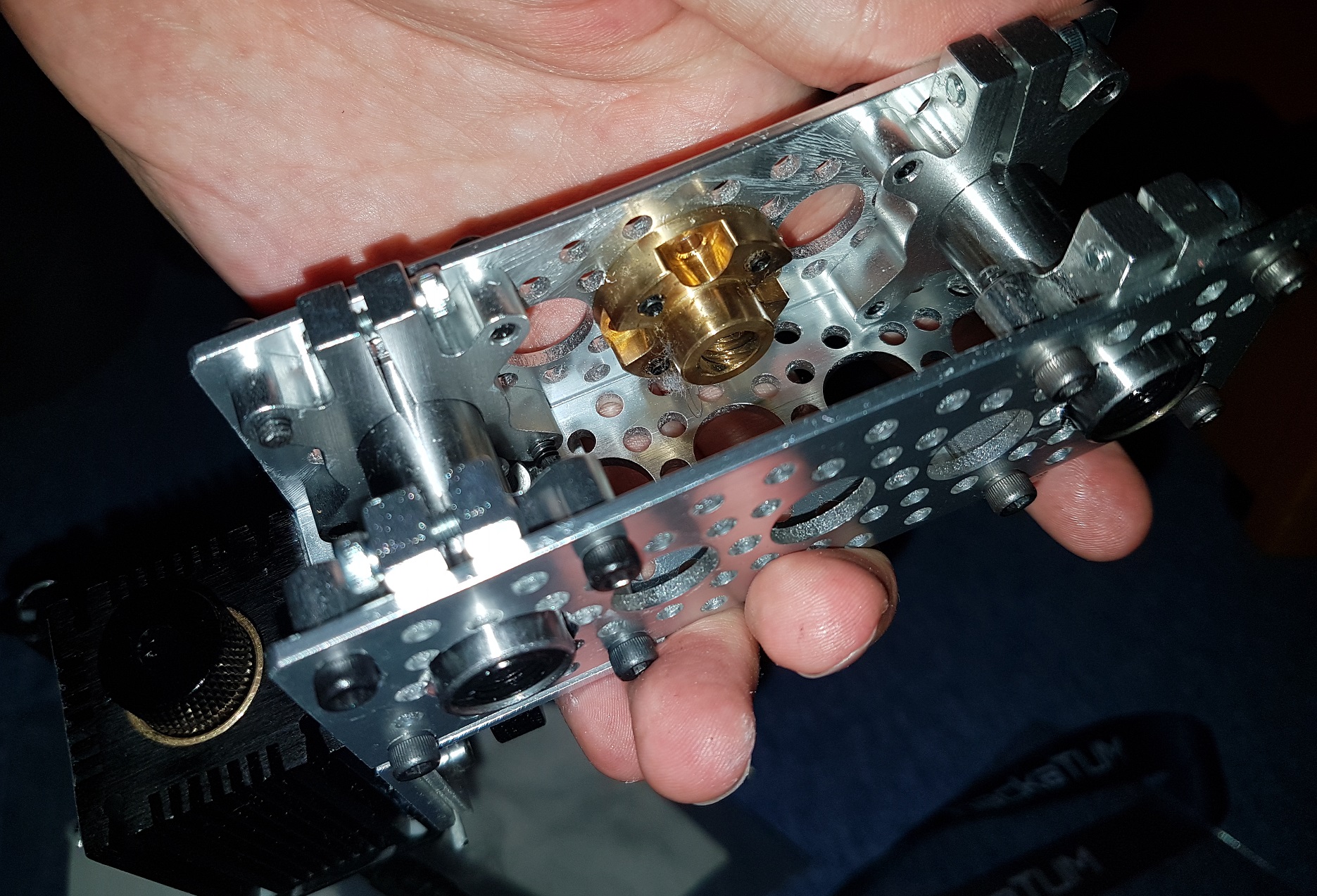

Building a Laser Cutter: Part 5 – Bearing Upgrades

After two years of usage, the x carriage of my laser cutter became rather wobbly. Wobbling! My old nemesis! What should I do? First, I tried to use different bearings. I bought some DryLin PTFE self-lubricating plastic bearings: https://www.amazon.de/gp/product/B01M328GIR ~5€ But they were no use in my configuration. They tended to bind, and what’s worse, were a lot more flexible… Read More →

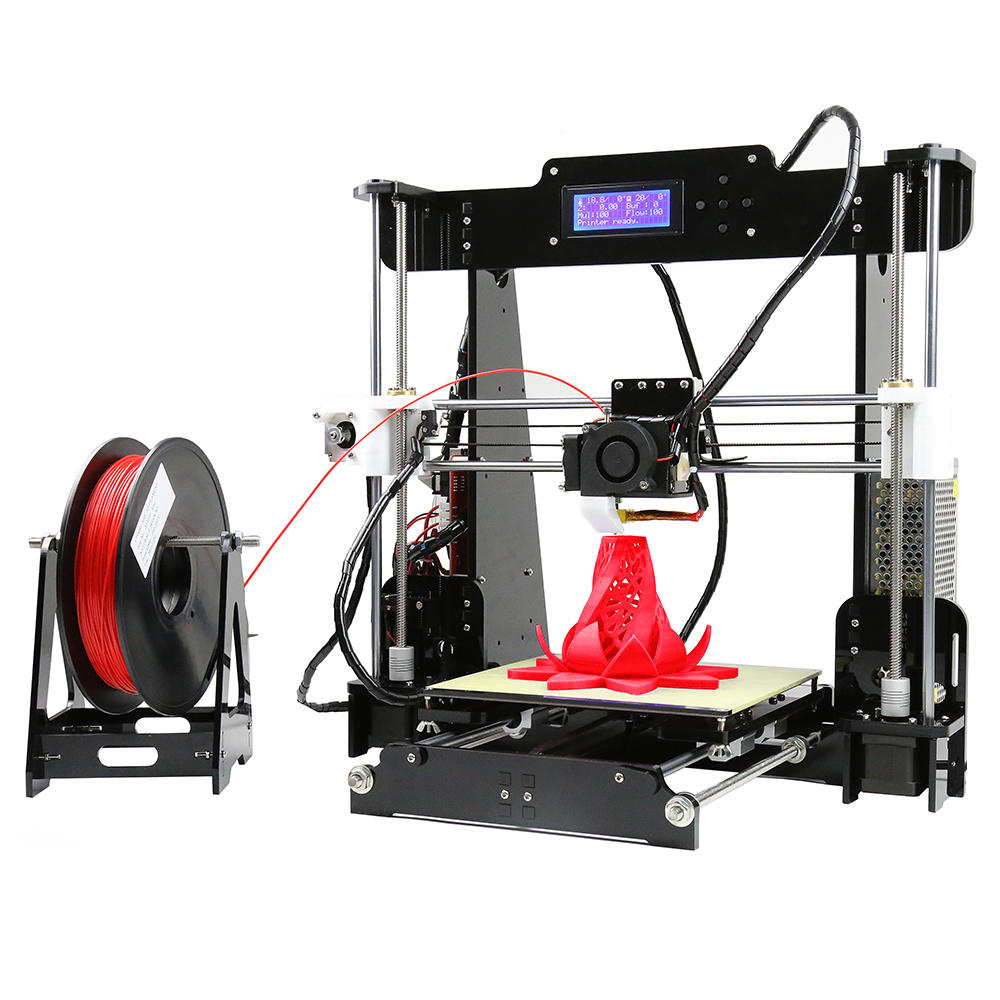

Pimp My 3D Printer

Adventures in tuning my Anet-A8 3D Printer. About a year ago, I purchased a rather inexpensive “DIY” 3D printer kit directly from the country that sells everything; China. My model of choice was the “Anet-A8” printer, due to its low price and big online support community. Not only the price and support led to my decision, but also the potential… Read More →

A DIY Handbrake for Simracing

Of course, there is always a Need for Speed in racing simulations. But sometimes, there is also the Need for Smooth Drifting Around Tight Corners. And pressing a button on my steering wheel controller just doesn’t cut it in terms of control and realism. So, I set out to acquire a handbrake controller, but quickly decided to build my own… Read More →

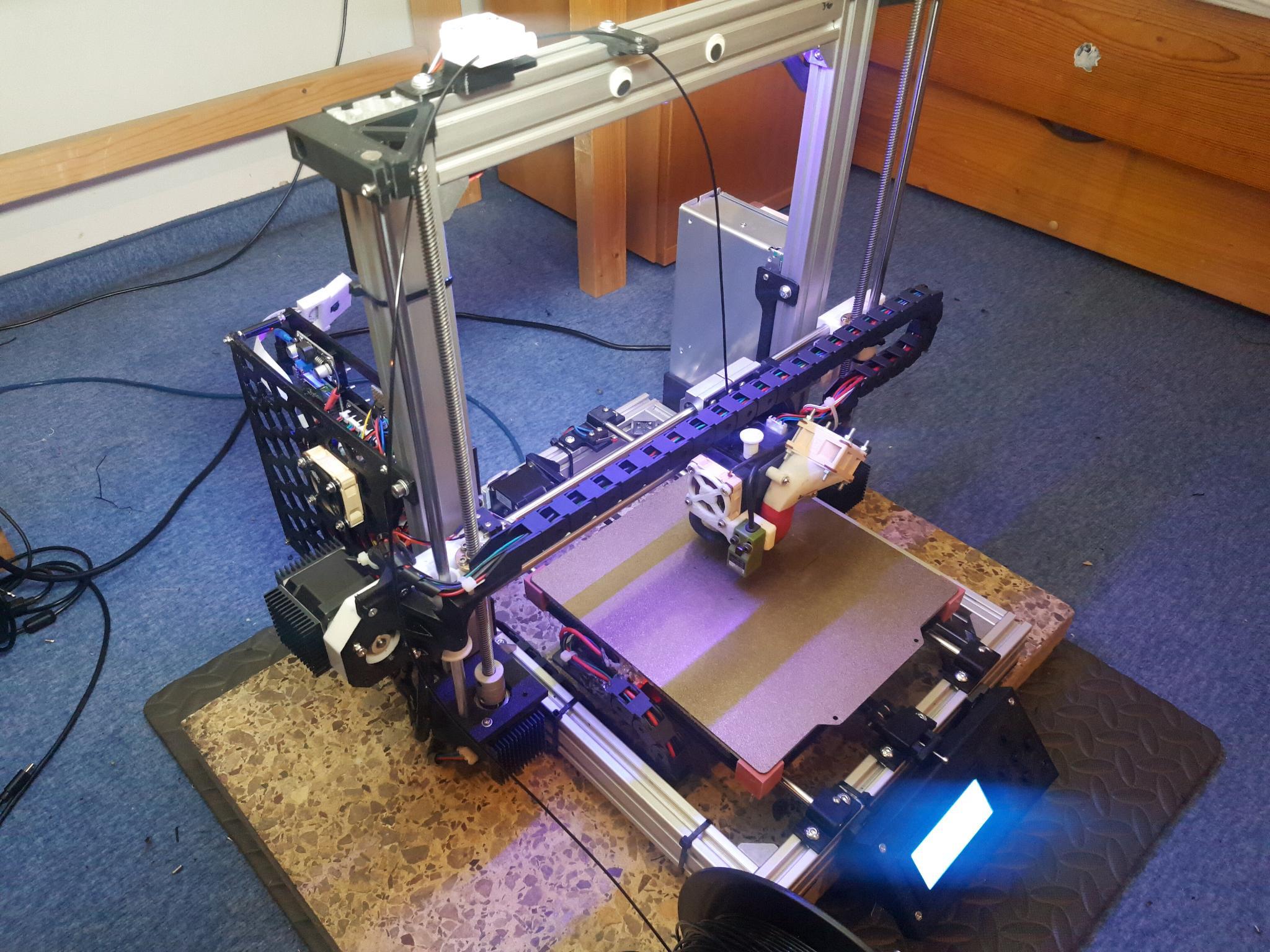

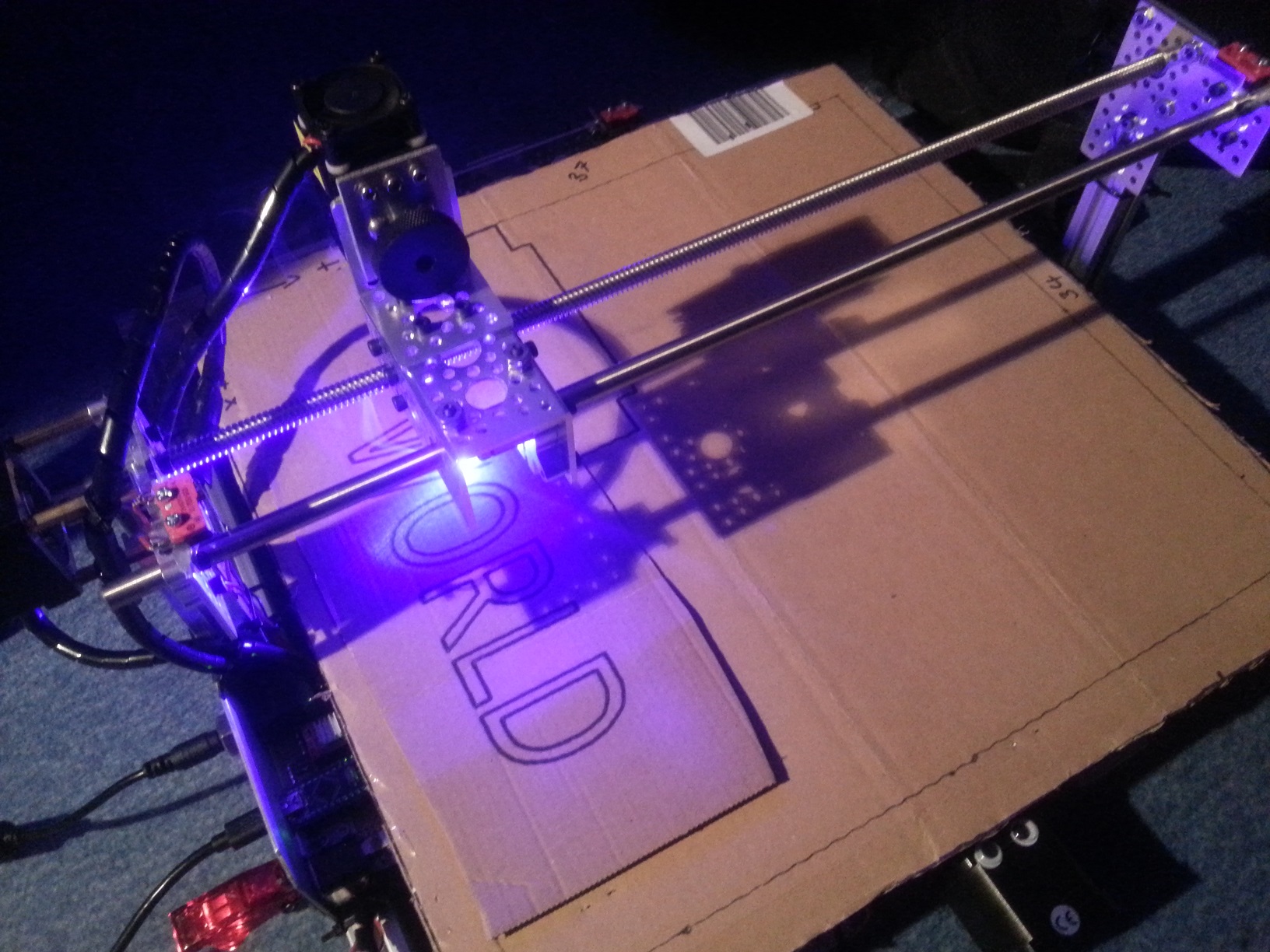

Building a Laser Cutter: Part 4 – Tests and Stability Improvements

The laser cutter is finally ready for testing! After securing the aluminium base plate (before that I had used carton) I powered up the system and sent my first gcode. Improving the Y Carriage Unfortunately, the lasered lines were rather wobbly. This was because the y carriage was only supported by one shaft. So, I ordered more parts. From Steplab:… Read More →

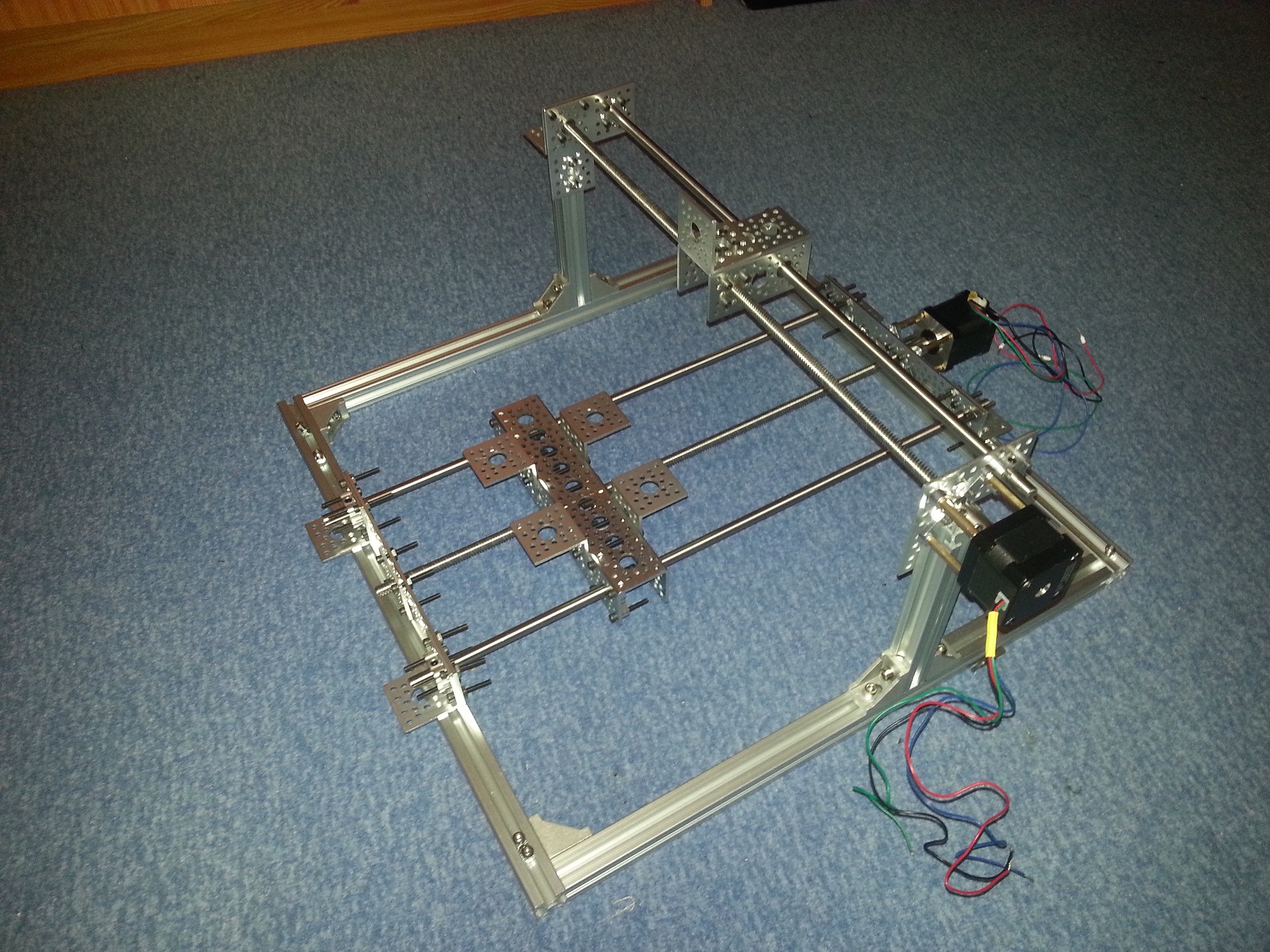

Building a Laser Cutter: Part 2 – Mechanical Build

After designing my laser cutter, the next step was to order the parts and assemble the machine. Because Actobotics parts are made and sold from USA, they are hard to come by in Europe (unless you want to pay high import taxes and shipping). In the end, I found an Italian shop (steplab.net / servocity.eu) which sold pretty much everything… Read More →

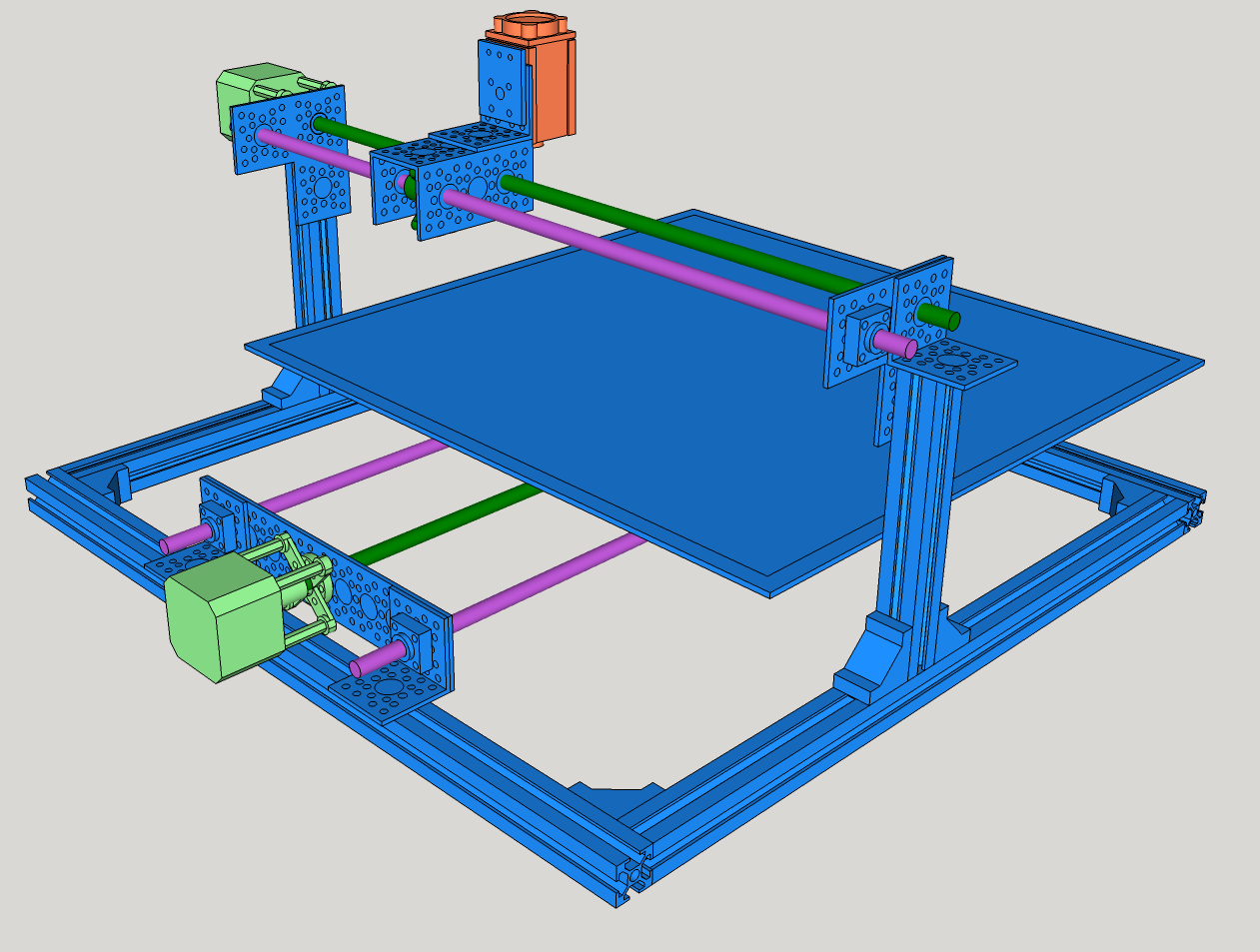

Building a Laser Cutter: Part 1 – Idea and Plan

In 2016, I built a CNC laser cutter / engraver. I always wanted to document the whole process, but never got around to do so – until now. Enjoy a multi-part series on how my build went! Before I start, a word of warning: Lasers can be very dangerous to your health, eyes and general envoirement if misused. Please make… Read More →